MANUFATURING FACILITIES

INJECTION MOLDING

Pak Auto Engineering's injection molding manufacturing facility is a state-of-the-art operation dedicated to producing high-quality automotive components. Equipped with advanced machinery and technology, the facility enables precise and efficient production processes. The manufacturing process begins with careful design and engineering, ensuring that each component meets exact specifications and quality standards. Utilizing injection molding techniques, molten material is injected into molds with precision, resulting in consistently shaped and detailed parts. Pak Auto Engineering's facility prioritizes quality control at every stage of production, with rigorous inspections and testing procedures in place to maintain product integrity. Additionally, the facility adheres to strict safety protocols to ensure a secure working environment for its skilled workforce. With a focus on innovation and excellence, Pak Auto Engineering's injection molding facility is capable of producing a wide range of automotive components efficiently and reliably, meeting the demands of clients and industry standards alike.

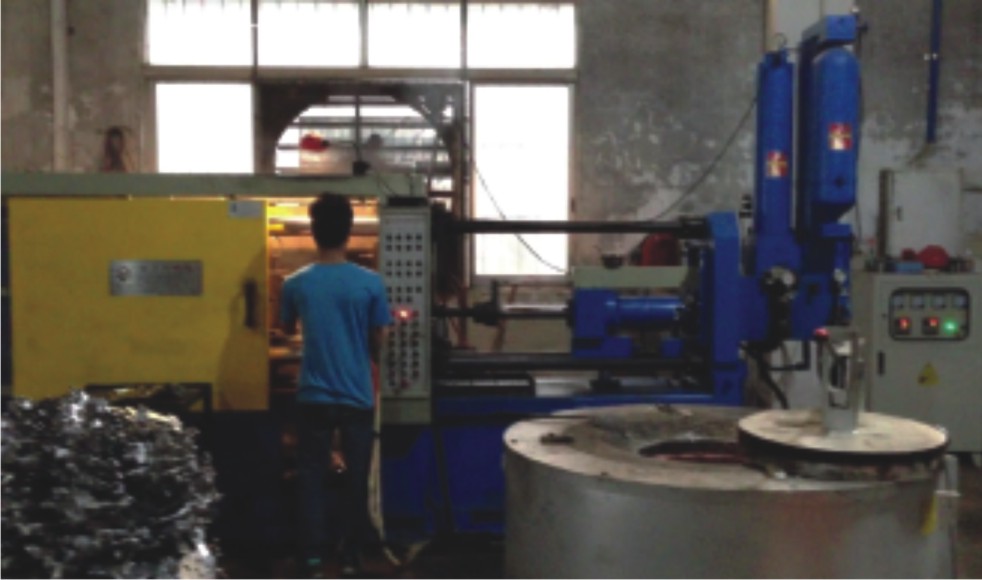

Die Casting

Pak Auto Engineering's die casting manufacturing facility is a cutting-edge operation dedicated to producing precision automotive components. Equipped with advanced die casting machinery and technology, the facility enables efficient and high-volume production processes. The manufacturing process begins with meticulous design and engineering, ensuring that each die meets exact specifications and quality standards. Molten metal is then injected into precision-crafted dies under high pressure, resulting in intricately shaped and detailed parts with exceptional accuracy and consistency. Quality control is paramount at every stage of production, with comprehensive inspections and testing procedures in place to maintain product integrity. Additionally, the facility upholds stringent safety protocols to ensure a secure working environment for its skilled workforce. Pak Auto Engineering's die casting facility is committed to innovation and excellence, capable of producing a diverse range of automotive components with superior quality and efficiency, meeting the demands of clients and industry standards alike.

Wire Manufacturing

Pak Auto Engineering's wire manufacturing facility is a modern and specialized operation focused on producing high-quality automotive wires. Equipped with advanced machinery and technology, the facility enables precise and efficient production processes. The manufacturing process begins with the selection of high-grade materials, ensuring the wires meet stringent quality standards. These materials are then carefully processed and treated to achieve the desired conductivity, flexibility, and durability required for automotive applications. Pak Auto Engineering's facility utilizes state-of-the-art wire extrusion machines to precisely shape and insulate the wires. Rigorous quality control measures are implemented throughout the production process to ensure consistency and reliability in the final product.

PRESS WORK

Pak Auto Engineering's press work manufacturing facility is a sophisticated operation specializing in the production of precision automotive components. Equipped with advanced press machines and technology, the facility enables efficient and accurate manufacturing processes. The manufacturing process begins with meticulous design and engineering, ensuring that each component meets exact specifications and quality standards. High-quality materials are carefully selected and fed into the press machines, where they undergo precise shaping and forming processes. Pak Auto Engineering's facility utilizes a variety of press techniques, including stamping, punching, and forming, to create intricate and complex components with consistent quality and reliability. Rigorous quality control measures are implemented throughout the production process to ensure the integrity of each part

ASSEMBLING

Pak Auto Engineering's assembling facility is a state-of-the-art operation dedicated to the meticulous construction of automotive components and systems. Equipped with advanced assembly lines and technology, the facility enables efficient and precise assembly processes. The manufacturing process begins with the procurement of high-quality components and parts from trusted suppliers. These components are then carefully inspected and prepared for assembly. Pak Auto Engineering's skilled technicians utilize specialized tools and equipment to methodically assemble the components according to exact specifications and quality standards.

PACKING

Pak Auto Engineering's packing facility is a modern and efficient operation dedicated to ensuring the safe and secure packaging of automotive components. Equipped with advanced packaging machinery and technology, the facility enables streamlined and effective packaging processes. The packaging process begins with the careful selection of packaging materials, including boxes, containers, padding, and seals, to provide optimal protection for the components during storage and transit. Pak Auto Engineering's packaging experts utilize automated systems to efficiently package the components according to customer requirements and industry standards.